Email: hujin@chinahujin.cn

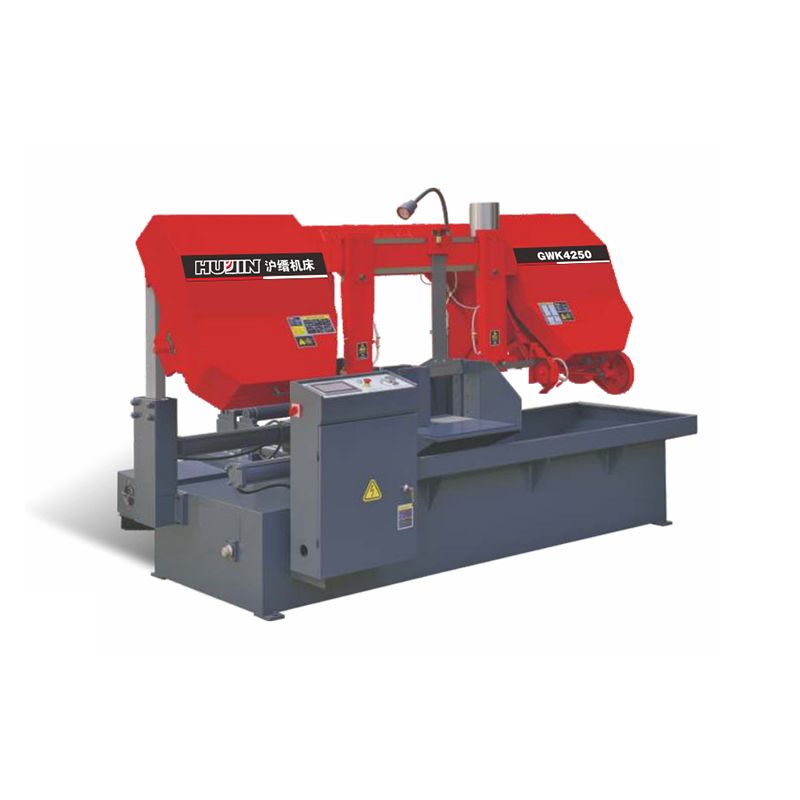

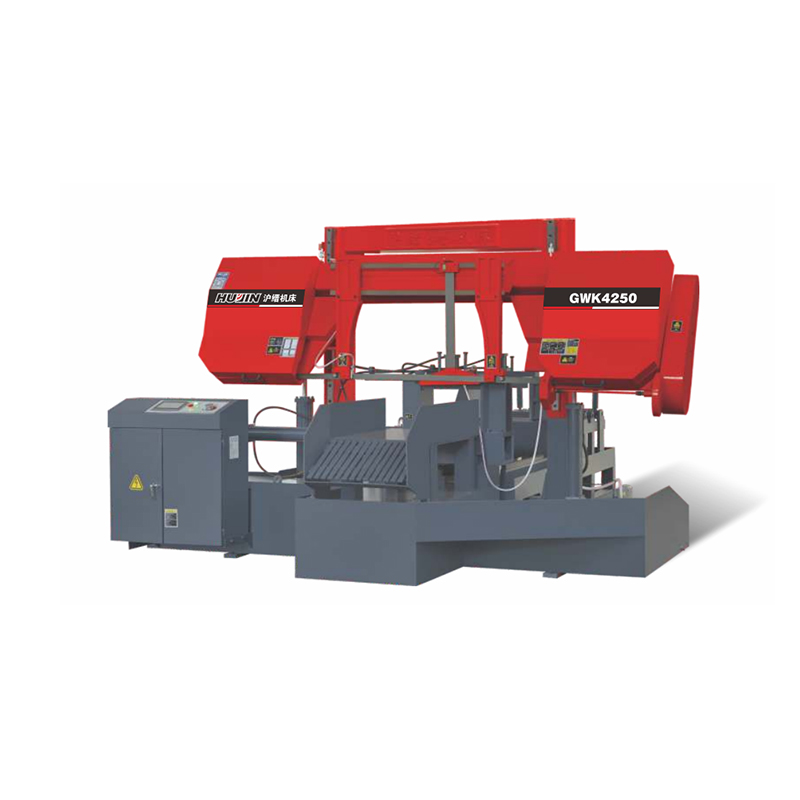

The Role of High Speed Cutting Machines in Modern Metalworking Practices

In the modern metalworking industry, speed and precision are crucial for maintaining competitive advantage and meeting production demands. High-speed cutting machines are playing an increasingly vital role in this landscape, offering significant enhancements in efficiency and accuracy. This article explores the advantages of high-speed cutting machines and their integration with metal cutting bandsaw machines and CNC machine cutting tools.

Advantages of High-Speed Cutting Machines

1. Boosted Productivity

High-speed cutting machines are designed to cut metal materials at accelerated rates, significantly improving productivity. Their rapid cutting capabilities streamline production processes, allowing manufacturers to handle high volumes of material efficiently. This is especially beneficial in sectors like automotive and aerospace, where large quantities of metal components are required. By reducing cutting times, high-speed machines enable faster turnaround and shorter production cycles, aligning with the industry's fast-paced demands.

2. Precision and Consistency

Despite their speed, high-speed cutting machines do not compromise on precision. Advanced technology ensures that these machines deliver accurate and consistent cuts, crucial for high-quality metal components. Integrating CNC machine cutting tools further enhances this precision by allowing programmable control and automated adjustments. This combination ensures that manufacturers achieve exact tolerances and maintain consistency across large production runs.

3. Versatility

High-speed cutting machines are versatile, capable of processing a variety of metal types, including steel, aluminum, and alloys. This versatility is crucial in meeting diverse manufacturing needs. When paired with metal cutting bandsaw machines, high-speed technology can handle both large, thick sections and intricate profiles with ease. This adaptability makes high-speed cutting machines valuable assets in a wide range of metalworking applications.

Integration with Metal Cutting Bandsaw Machines

1. Enhanced Efficiency

Integrating high-speed cutting technology with metal cutting bandsaw machines improves efficiency significantly. Bandsaw machines, known for their ability to handle large and thick materials, benefit from faster cutting speeds. This synergy streamlines operations, reduces production times, and enhances overall productivity. High-speed cutting enables bandsaw machines to process materials more quickly while maintaining high-quality cuts.

2. Improved Performance

The performance of metal cutting bandsaw machines is significantly enhanced by high-speed cutting technology. Faster cutting speeds and better material handling capabilities result in smoother operations and increased throughput. This is particularly beneficial in high-volume manufacturing environments where precision and speed are crucial.

3. Reduced Downtime

High-speed cutting machines help reduce downtime by speeding up the cutting process and minimizing the time required for each operation. This reduction in downtime translates to higher productivity and allows manufacturers to meet tight production schedules more effectively.

The Role of CNC Machine Cutting Tools

1. Programmable Precision

CNC machine cutting tools play a crucial role in improving the benefits of high-speed cutting machines. CNC technology enables programmable precision, allowing operators to set exact cutting parameters and patterns. This capability ensures high accuracy and consistency, which is essential for producing complex metal components. High-speed cutting machines equipped with CNC tools can execute intricate cuts with minimal manual intervention.

2. Automation and Efficiency

The integration of CNC technology with high-speed cutting machines enhances automation and efficiency. Automated feeding systems and real-time monitoring contribute to streamlined operations and reduced labor costs. This combination ensures that manufacturers can achieve high production rates while maintaining quality.

3. Flexibility

CNC machine cutting tools add flexibility to high-speed cutting machines, allowing for a wide range of cutting options and adjustments. This flexibility is valuable for industries requiring custom or varied metal components. The ability to quickly adapt to different projects and materials is a significant advantage in today's dynamic manufacturing environment.

High-speed cutting machines are transforming modern metalworking practices by offering enhanced productivity, precision, and versatility. Their integration with metal cutting bandsaw machines and CNC machine cutting tools further amplifies these benefits, resulting in more efficient and accurate manufacturing processes.

English

English русский

русский عربى

عربى