Email: hujin@chinahujin.cn

An In-Depth Analysis of the Cutting Precision of Small Bandsaw Machines

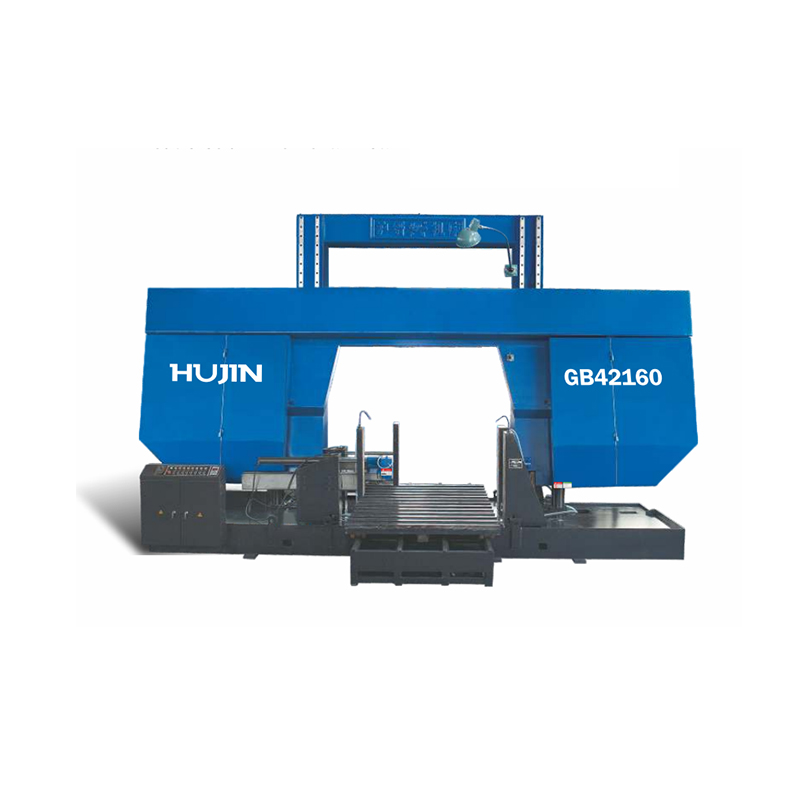

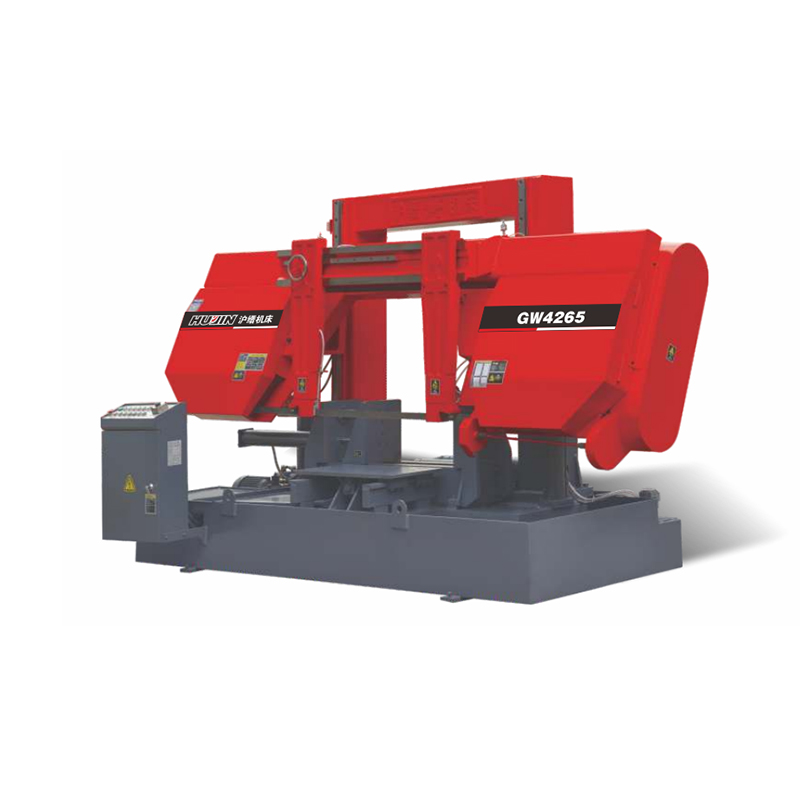

Wholesale OEM Small Bandsaw Machine Manufacturer in China

In the world of woodworking and metalworking, precision is paramount. The small bandsaw machine, a compact and versatile tool, has become an indispensable piece of equipment for hobbyists and professionals alike. Its ability to deliver clean, accurate cuts is a testament to the engineering and design that goes into its creation. This article delves into the intricacies of the small bandsaw machine's cutting precision, examining the factors that contribute to its performance and how it can be optimized for various applications.

The small bandsaw machine's precision is a result of several key components working in harmony. The blade, which is the primary cutting element, plays a crucial role in determining the quality of the cut. High-quality blades are made from materials that maintain their sharpness over time and resist wear, ensuring that the small bandsaw machine can produce consistent, accurate cuts. The tension of the blade is another critical factor; a properly tensioned blade will track straight and true, reducing the risk of wobble or deviation from the intended cutting path.

The small bandsaw machine's frame and guide system also contribute to its cutting precision. A sturdy frame ensures that the machine remains stable during operation, reducing vibrations that can cause imprecise cuts. The guide system, which includes the upper and lower guides, must be aligned correctly to ensure that the blade remains on the desired path. Misalignment can result in uneven cuts or damage to the material being worked on.

The small bandsaw machine's motor and speed control are also integral to its precision. A powerful motor provides the necessary torque to drive the blade through various materials, while speed control allows the operator to adjust the cutting speed to suit the specific task at hand. Slowing down the blade speed can improve precision, especially when working with delicate materials or making intricate cuts.

The operator's skill and experience also play a significant role in the small bandsaw machine's cutting precision. A skilled operator will know how to properly set up the machine, select the appropriate blade, and make adjustments as needed to achieve the desired cut. Proper technique, such as maintaining a steady hand and ensuring that the material is securely clamped in place, is essential for achieving precision.

Environmental factors can also impact the small bandsaw machine's cutting precision. Temperature and humidity can affect the material being cut, causing it to expand or contract, which can cause inaccuracies in the final product. Ensuring that the machine and the workspace are kept at a consistent temperature and humidity level can help mitigate these issues.

Regular maintenance is crucial for maintaining the small bandsaw machine's cutting precision. This includes keeping the blade sharp, checking and adjusting the tension, and ensuring that the guide system is clean and free of debris. A well-maintained machine will perform more accurately and consistently over time.

In conclusion, the cutting precision of a small bandsaw machine is a complex interplay of various factors, including the quality of the blade, the stability of the frame, the alignment of the guide system, the power and control of the motor, the skill of the operator, and the environmental conditions in which the machine is used. By understanding and addressing these factors, users can optimize their small bandsaw machines for a high level of precision in their cutting tasks. Whether for woodworking, metalworking, or other applications, a small bandsaw machine that is properly maintained and operated can deliver the accuracy and consistency that professionals and hobbyists alike demand.

English

English русский

русский عربى

عربى