Email: hujin@chinahujin.cn

- Home

- About

- Product

- NC Double-Column Horizontal Band Sawing Machine

- Horizontal Band Sawing Machine

- Rotary Horizontal Band Sawing Machine

- Double-Column Horizontal Metal Band Sawing Machine

- Vertical Band Sawing Machine

- NC Intelligent And Efficient Horizontal Band Sawing Machine

- Profile Cutting

- CNC High Speed Metal Circular Sawing Machine

- Service

- News

- Contact

INQUIRY NOW

Web Menu

- Home

- About

- Product

- NC Double-Column Horizontal Band Sawing Machine

- Horizontal Band Sawing Machine

- Rotary Horizontal Band Sawing Machine

- Double-Column Horizontal Metal Band Sawing Machine

- Vertical Band Sawing Machine

- NC Intelligent And Efficient Horizontal Band Sawing Machine

- Profile Cutting

- CNC High Speed Metal Circular Sawing Machine

- Service

- News

- Contact

Product Search

Exit Menu

Mastering Tension Adjustments for Double Column Band Saw Performance

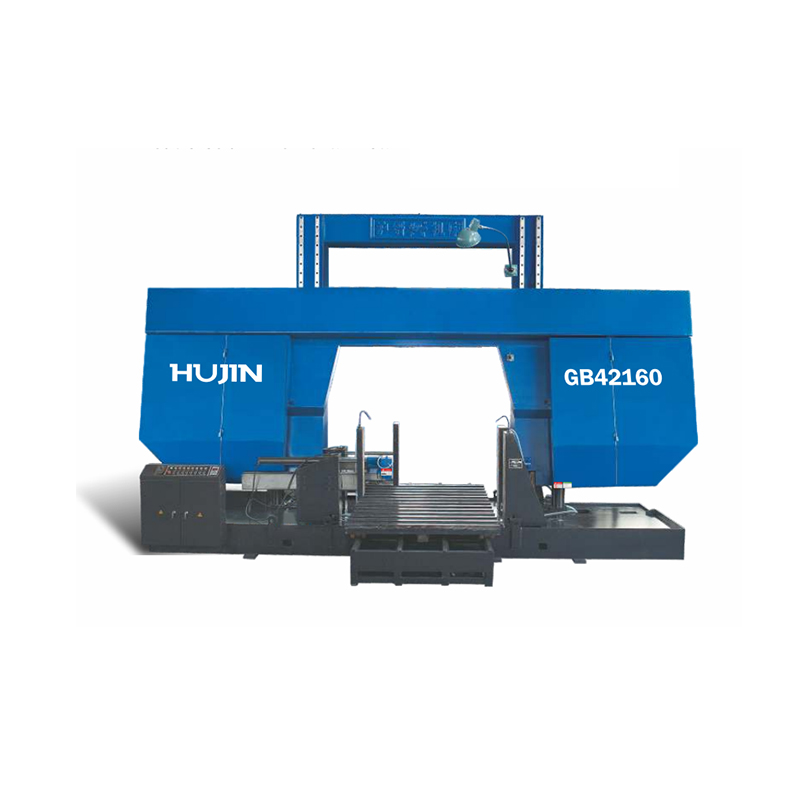

China Design Automatic Double Column Band Saw Wholesaler

The Double Column Band Saw, a pivotal tool in the metalworking industry, is renowned for its precision and efficiency in cutting a variety of materials. A critical aspect of ensuring the saw's suitable performance is the correct adjustment of the band saw's tension. This article delves into the intricacies of tension adjustment for Double Column Band Saws, a process that is essential for maintaining the longevity of the saw and the quality of the cuts it produces.

The tension of the band saw is a delicate balance that must be carefully managed. Too loose, and the band can slip or vibrate excessively, causing inaccurate cuts and potential damage to the saw. Too tight, and the band can overstretch, causing it to break or wear out prematurely. Understanding how to adjust the tension of a Double Column Band Saw is therefore crucial for operators and maintenance personnel.

The process of adjusting the tension on a Double Column Band Saw begins with an understanding of the saw's components. The band, which is the primary cutting tool, is guided by wheels and tensioned by a system of springs or hydraulic mechanisms. The tension must be adjusted according to the width, thickness, and material type of the band, as well as the specific cutting requirements of the job at hand.

To adjust the tension on a Double Column Band Saw, one must ensure that the saw is powered off and that all safety protocols are observed. The band should be inspected for any signs of damage or wear, as a damaged band can affect the tension settings and the quality of the cuts. If the band is in good condition, the operator can proceed to the tension adjustment mechanism, which is typically located on the side of the saw.

For Double Column Band Saws that use a spring system, the operator will need to loosen the adjustment bolts to relieve the tension on the band. The band should then be positioned correctly on the wheels, and the adjustment bolts can be retightened to the manufacturer's recommended torque settings. It's important to consult the saw's manual for specific instructions, as different models may have varying tension requirements.

Hydraulic tension systems on Double Column Band Saws offer a more precise method of tension adjustment. These systems use a hydraulic cylinder to apply pressure to the band, and the tension can be adjusted by changing the pressure in the cylinder. The operator will need to refer to the saw's manual to determine the appropriate pressure settings for the specific band and cutting task. Once the correct pressure is set, the hydraulic system will maintain the tension automatically, ensuring consistent performance throughout the cutting process.

Regular monitoring and adjustment of the Double Column Band Saw's band tension are essential for maintaining the saw's performance and preventing accidents. The tension should be checked after every few hours of operation, especially during long cutting sessions or when cutting hard materials. Any changes in the band's condition, such as stretching or wear, will require a readjustment of the tension to maintain suitable cutting performance.

In conclusion, the art of adjusting the tension on a Double Column Band Saw is a critical skill for operators and maintenance personnel. By understanding the importance of proper tension and following the manufacturer's guidelines for adjustment, users can ensure that their Double Column Band Saws remain efficient, safe, and productive. Proper tension adjustment not only prolongs the life of the band saw but also guarantees the quality of the cuts, which is paramount in any metalworking operation.

Get in touch

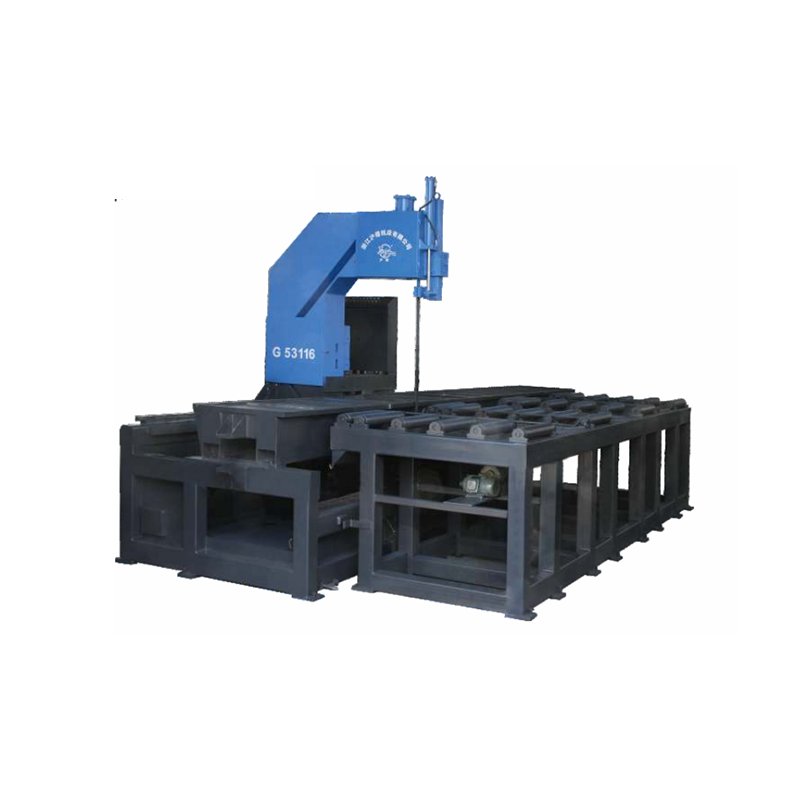

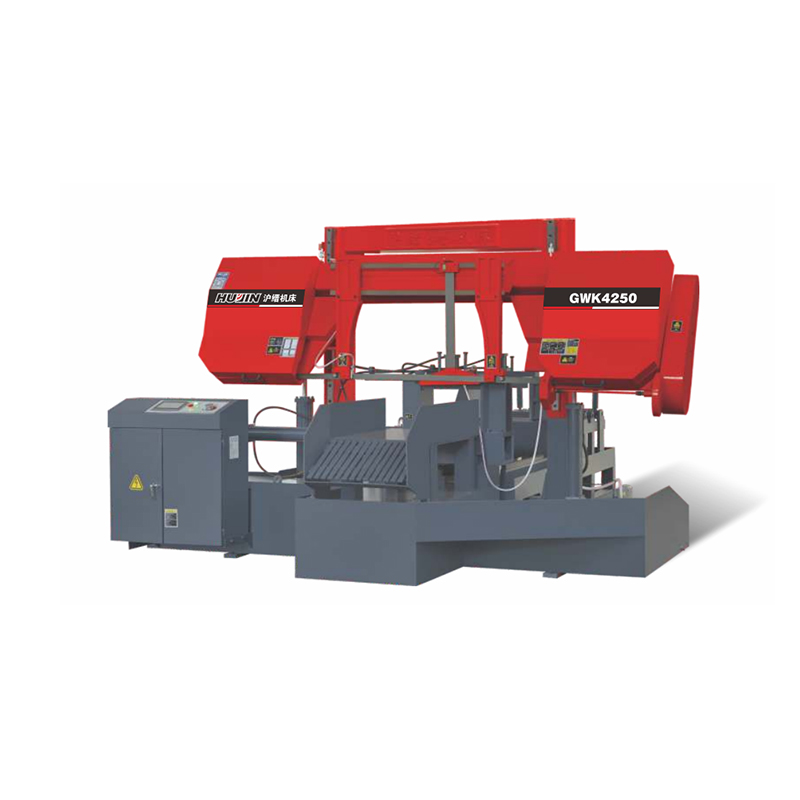

Related Products

Zhejiang Hujin Machine Tool Co., Ltd. is a professional manufacturer specializing in the production of "Hurein" series hydraulic presses, band saws and milling machines.

Contact Information

phone: +86-18805885558

+86-13395785558

Email: hujin@chinahujin.cn

Add: No. 300, Xingda Road, Jinxiu Industrial Park, Huzhen Town, Jinyun County, Zhejiang Province, China 321404

Mobile Site

English

English русский

русский عربى

عربى