Email: hujin@chinahujin.cn

Comparative Efficiency Analysis of Double Column Band Saws vs. Single Column Band Saws

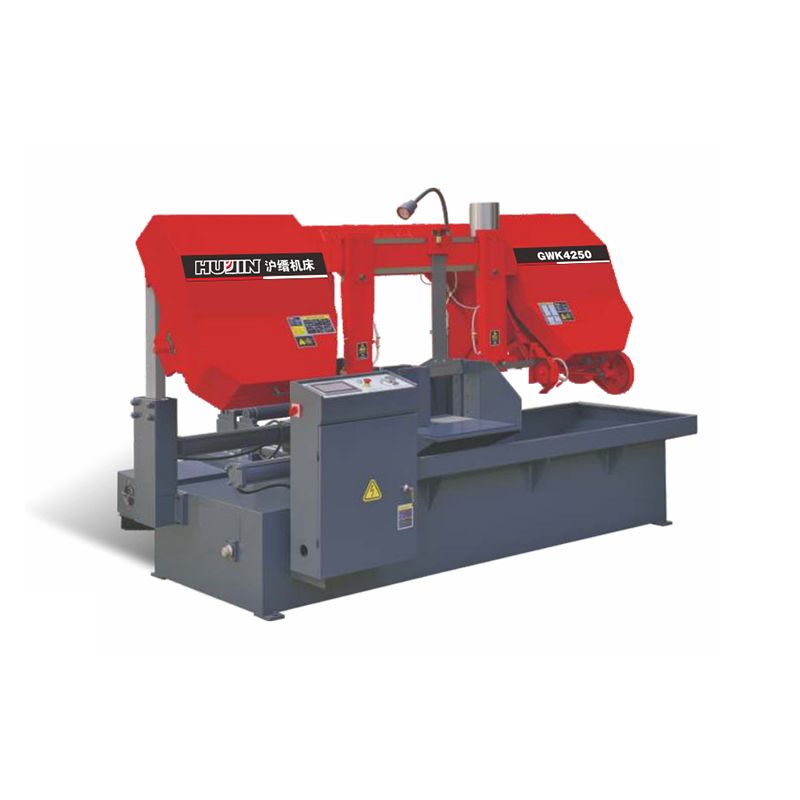

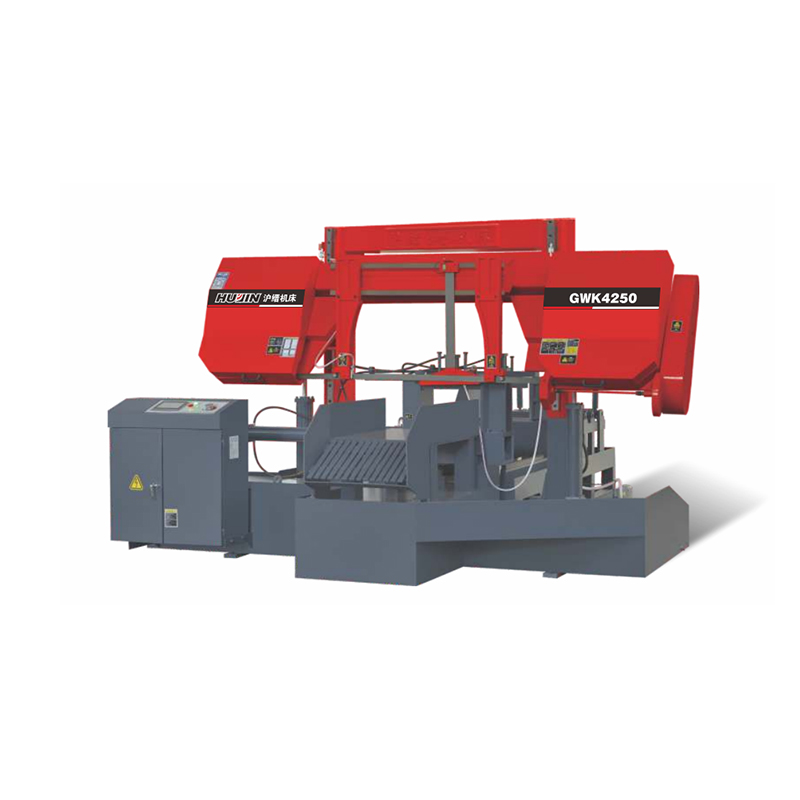

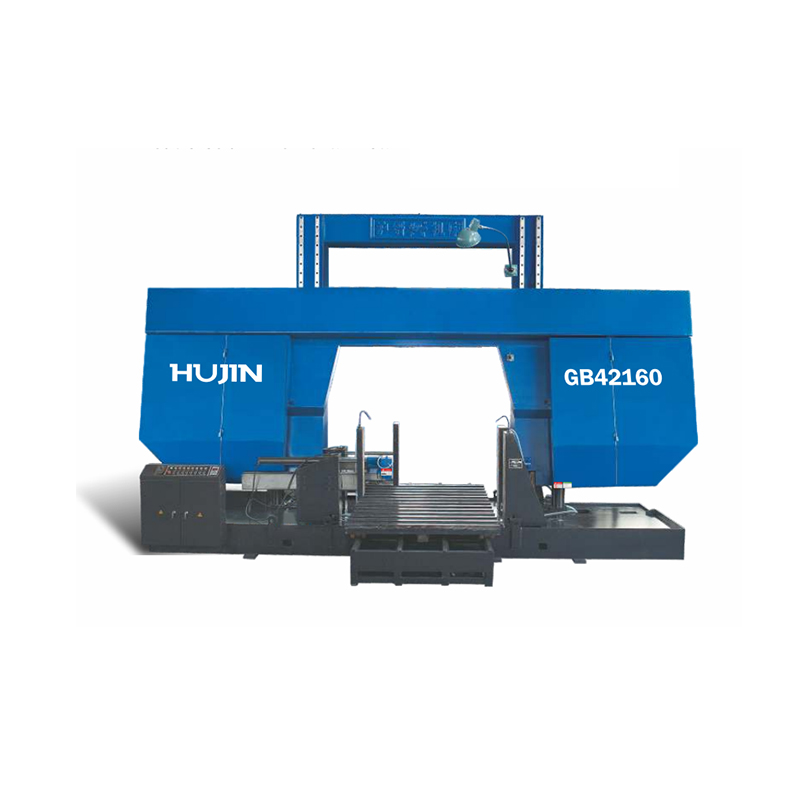

Sale Automatic Double Column Band Saw Manufacturing Factory

In the realm of metal cutting, the Double Column Band Saw stands as a formidable competitor to the traditional Single Column Band Saw. The question of efficiency is central to understanding the advantages and disadvantages of each type of saw. This article aims to explore the differences in work efficiency between Double Column Band Saws and Single Column Band Saws, highlighting the factors that contribute to their respective performance levels.

The Double Column Band Saw, with its robust design, offers a stable and rigid cutting platform. This stability is crucial for maintaining precision during heavy-duty operations, which is often a requirement in industries such as construction, automotive, and aerospace. The double-column structure provides a larger surface area for the saw blade to travel, allowing for longer cutting lengths without the need for repositioning the material or the saw itself. This feature alone can significantly increase the efficiency of the Double Column Band Saw, as it reduces the time spent on setup and repositioning, which are common with Single Column Band Saws.

The rigidity of the double-column frame also allows for the use of larger and more powerful motors, which can drive the saw blade at higher speeds. This results in faster cutting times and increased productivity. Single Column Band Saws, limited by their single-column design, are usually unable to carry oversized motors, which limits their cutting speed and therefore affects work efficiency.

Another aspect to consider is the cutting force distribution. In a Double Column Band Saw, the force is evenly distributed across the two columns, reducing the risk of blade deflection and ensuring a straight and accurate cut. Single Column Band Saws, on the other hand, are more prone to blade deflection due to the concentration of force on a single point, which can cause less precise cuts and the need for additional passes to achieve the desired finish.

Maintenance and downtime are also critical factors in work efficiency. Double Column Band Saws, due to their heavier construction, often require less frequent maintenance and are more durable, causing less downtime. Single-band saws, while more affordable and easier to maneuver, may require more frequent maintenance and are more susceptible to wear and tear, which can interrupt production schedules.

The Double Column Band Saw's ability to handle larger and heavier materials is another point of comparison. The double-column design can support the weight of larger workpieces, allowing for the cutting of larger sections in a single operation. Single-band saws may struggle with heavy materials, as the single column may not provide adequate support, causing potential safety hazards and reduced efficiency.

In terms of versatility, Double Column Band Saws often come equipped with advanced features such as digital controls and automated feed systems, which can further enhance the cutting process. Single Column Band Saws, while more straightforward, may lack these advanced features, which can limit their efficiency in more complex cutting tasks.

Finally, the environmental impact of the two types of saws should not be overlooked. Double Column Band Saws, with their higher cutting speeds and precision, can reduce material waste and energy consumption. Single Column Band Saws may require more passes to achieve the same result, causing increased waste and energy use.

In conclusion, the Double Column Band Saw offers several advantages over the Single Column Band Saw in terms of work efficiency. Its stability, power, and advanced features contribute to faster cutting times, reduced downtime, and increased precision. While Single Column Band Saws have their place in certain applications, the Double Column Band Saw's good efficiency makes it an attractive choice for industries demanding high productivity and precision.

English

English русский

русский عربى

عربى