Email: hujin@chinahujin.cn

Innovations in Horizontal Cutting Saws for Better Performance

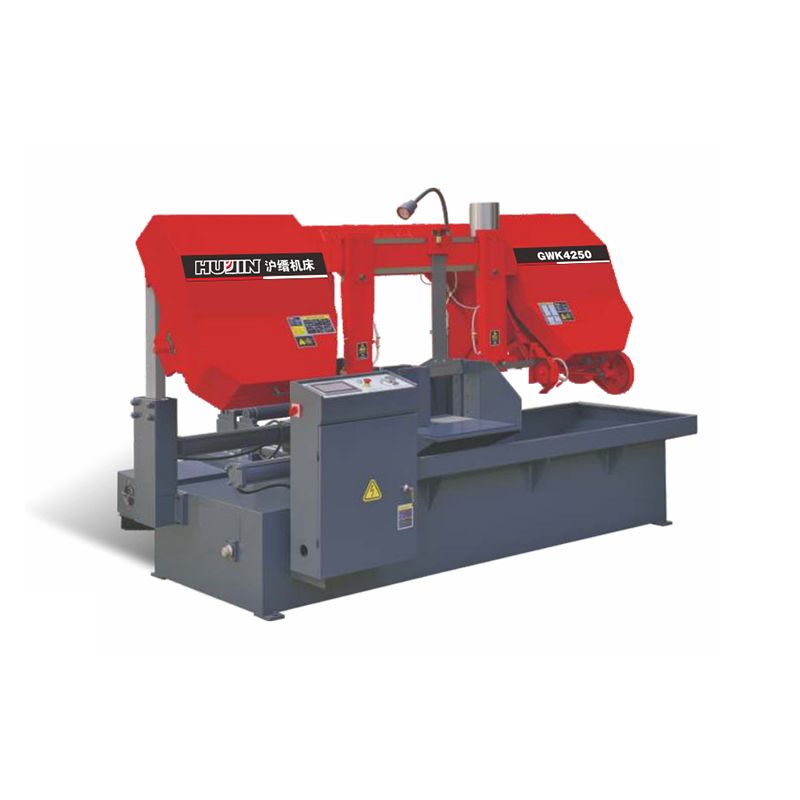

The evolution of metalworking technology has been nothing short of revolutionary, with innovations in horizontal cutting saws guideing the charge in enhancing performance and precision. These advancements have transformed the way industries approach metal cutting, offering solutions that are not only more efficient but also more precise and adaptable to various applications.

In the past, traditional metal cutting machines were often limited by their manual operation and lack of precision. However, with the advent of horizontal cutting saws, the metalworking industry has witnessed a significant leap forward. These saws are designed to cut metal in a horizontal position, which not only improves safety but also ensures a more stable and accurate cut.

CNC technology has been instrumental in the innovation of horizontal cutting saws. By automating the cutting process, these machines can execute complex patterns and shapes with a level of accuracy that was previously unattainable. The use of CNC in horizontal cutting saws has also reduced the time required for setup and operation, cause increased productivity and cost savings.

One of the key innovations in horizontal cutting saws is the focus on safety and ergonomics. With the saw blade positioned horizontally, operators are less likely to suffer from back strain or other physical discomforts associated with traditional vertical cutting methods. Additionally, the horizontal orientation of the blade reduces the risk of kickback, a common safety hazard in metal cutting.

The versatility of horizontal cutting saws is another area where innovation has made significant strides. These machines are now capable of handling a wide range of materials, from aluminum to steel, and can be adapted for various cutting tasks, including miter cuts, bevel cuts, and plunge cuts. This adaptability has broadened the applications of horizontal cutting saws across different industries.

While horizontal cutting saws have made great strides, the integration of vertical circular saw machine technology has further enhanced their capabilities. Vertical circular saw machines offer the advantage of cutting large diameter pipes and tubes, which can be challenging for traditional horizontal saws. By combining the strengths of both horizontal and vertical cutting saws, manufacturers can achieve a more comprehensive cutting solution.

The development of new blade materials and designs has also contributed to the performance of horizontal cutting saws. Advanced blade coatings, for example, reduce friction and heat during the cutting process, cause longer blade life and improved cut quality. Additionally, the use of high-speed steel (HSS) and carbide-tipped blades has allowed for faster cutting speeds and cleaner cuts.

The incorporation of automation and smart features in horizontal cutting saws has further improved their performance. Features such as automatic feed systems, digital readouts for cutting depth and angle, and even IoT connectivity for remote monitoring and diagnostics are now standard in many high-end models. These smart features not only increase the efficiency of the cutting process but also provide valuable data for process optimization and predictive maintenance.

As horizontal cutting saws become more sophisticated, the need for well-trained operators also increases. Manufacturers are investing in comprehensive training programs and support services to ensure that operators can fully utilize the capabilities of these advanced machines. This includes not only hands-on training but also access to online resources and technical support.

Looking ahead, the future of horizontal cutting saws is promising. With ongoing research and development, we can expect to see even more innovations in areas such as cutting speed, precision, and material compatibility. The integration of artificial intelligence and machine learning algorithms will likely play a significant role in the next generation of horizontal cutting saws, further enhancing their performance and adaptability.

English

English русский

русский عربى

عربى