Email: hujin@chinahujin.cn

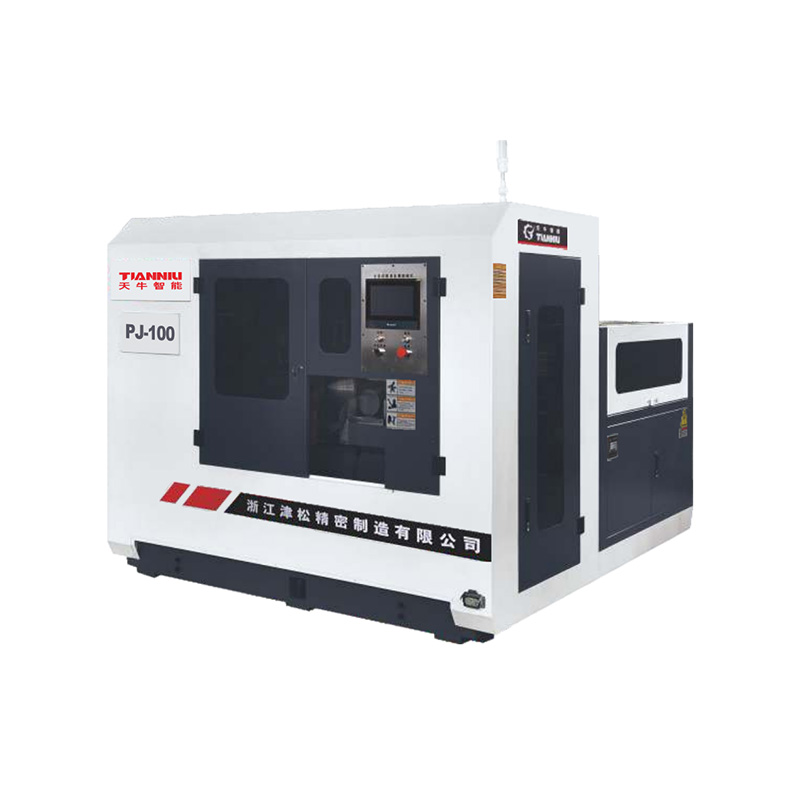

CNC Metal Saws Help Enhancing Precision and Efficiency in Metal Cutting

CNC metal saws have ushered in a new era of precision in metal cutting. These machines are designed to operate with computer numerical control, which allows for highly accurate and repeatable cuts. The integration of advanced software and hardware in CNC metal saws ensures that every cut is made to exact specifications, reducing waste and improving the quality of the final product.

High-speed metal saws are engineered to cut through metal at remarkable speeds, significantly reducing the time required for each cut. This increased speed does not compromise the precision of the cut; in fact, it often enhances it. The high-speed metal saws are capable of maintaining a consistent cutting speed, which is crucial for achieving uniformity in the final product. This efficiency is particularly valuable in high-volume production environments where time is of the essence.

Automatic metal saws take the concept of efficiency to the next level by eliminating the need for manual operation. These machines are programmed to perform a series of cuts without the need for human intervention. This not only speeds up the cutting process but also reduces the potential for human error. Automatic metal saws are ideal for repetitive tasks, ensuring that each cut is made with the same level of precision as the last.

The combination of precision and efficiency offered by CNC metal saws, high-speed metal saws, and automatic metal saws is a powerful one. These machines are capable of handling a wide range of materials, from aluminum to steel, with ease. The precision of CNC metal saws ensures that each cut is made to the exact dimensions required, while the high-speed capabilities of these saws reduce the time spent on each cut. Automatic metal saws further enhance this by removing the need for manual operation, allowing for a seamless and uninterrupted cutting process.

As the manufacturing industry continues to evolve, the demand for high-quality, precision-cut metal components has never been higher. CNC metal saws, high-speed metal saws, and automatic metal saws are meeting this demand by providing manufacturers with the tools they need to produce these components with speed and accuracy. These machines are adaptable to various cutting requirements, making them a versatile addition to any workshop or factory floor.

For businesses looking to invest in the future of metal cutting, CNC metal saws, high-speed metal saws, and automatic metal saws represent a significant opportunity. These machines not only improve the quality and efficiency of the cutting process but also contribute to a more sustainable manufacturing process by reducing waste and minimizing the need for manual labor.

The integration of CNC metal saws, high-speed metal saws, and automatic metal saws in the metalworking industry has been transformative. These machines have redefined the standards of precision and efficiency in metal cutting. As technology continues to advance, it is expected that these saws will only become more sophisticated, further enhancing their capabilities and solidifying their place as indispensable tools in the modern manufacturing landscape.

CNC metal saws significantly improve precision and efficiency in metal cutting processes. These computer-numerically-controlled saws automate cutting tasks, ensuring consistent and accurate results. They reduce human error, minimize material waste, and speed up production times. Advanced features like programmable cutting paths and variable speed control further optimize the cutting process, making CNC metal saws a key asset in modern manufacturing.

English

English русский

русский عربى

عربى