Email: hujin@chinahujin.cn

Safety Guidelines for Operating a Metal Portable Band Saw in the Workshop

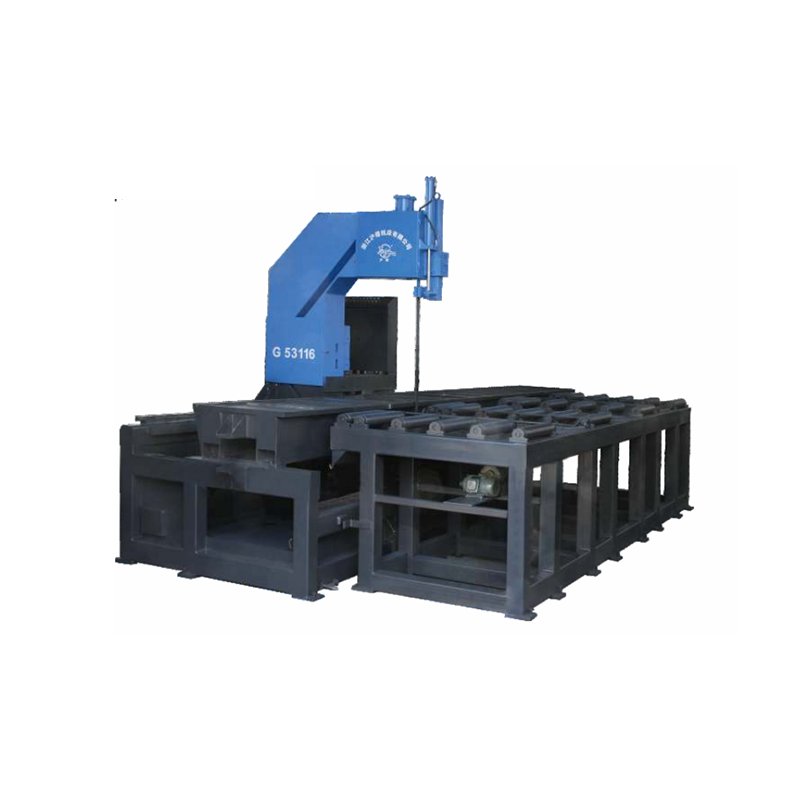

Before operating any power tool, it is essential to understand its components and functions. The wide mouth portable band saw, for instance, is designed with a larger throat capacity, allowing for cutting larger materials with ease. Familiarize yourself with the saw's blade tension system, blade guide, and emergency stop mechanism.

Regular inspection and maintenance are crucial for the safe operation of any power tool. For the portable horizontal band saw, check the blade for any signs of wear or damage before each use. Ensure that the blade is properly aligned and tensioned. Lubricate the guide bearings and other moving parts to prevent friction and heat buildup.

Wearing the appropriate PPE is non-negotiable when operating a metal portable band saw. Safety glasses or goggles should be worn to protect the eyes from flying debris. Hearing protection is also recommended due to the high noise levels generated during operation. Gloves should be avoided as they can get caught in the moving parts of the saw.

Securing the workpiece is vital to prevent it from moving during the cutting process. Use clamps or a vise to hold the material in place. Ensure that the workpiece is stable and does not have any loose parts that could cause it to shift during operation.

The choice of blade is crucial for the safe and efficient operation of a portable horizontal band saw. Select a blade that is appropriate for the material being cut. The wrong blade can cause poor cuts, increased risk of kickback, and potential injury.

When operating a metal portable band saw, always follow safe cutting practices. Cut away from your body and maintain a firm grip on the workpiece. Do not force the cut; let the saw do the work. Keep your fingers clear of the blade at all times.

Know the location and function of the emergency stop button on your wide mouth portable band saw. In the event of an emergency, such as the workpiece binding or the blade breaking, quickly activate the emergency stop to prevent further damage or injury.

Ensure that all operators of the portable horizontal band saw are adequately trained in its safe use. Training should cover the operation of the saw, safety procedures, and emergency response. Supervision of new operators is recommended until they are proficient in the safe use of the saw.

A clutter-free and well-organized workspace is essential for safety. Keep the area around the metal portable band saw clear of debris and other materials that could cause tripping hazards. Ensure that all tools and equipment are stored properly when not in use.

Fatigue can cause mistakes and accidents. Encourage operators to take regular breaks to rest and refresh. This practice not only improves safety but also enhances productivity and focus.

After using the wide mouth portable band saw, follow proper after-use procedures. Turn off and unplug the saw, and ensure that the blade has come to a complete stop. Clean the saw and work area, removing any metal shavings or debris that could cause slips or falls.

Safety is an ongoing process. Regularly review and update safety guidelines and procedures to reflect new practices, technological advancements, and lessons learned from past incidents.

The safe operation of a metal portable band saw in the workshop requires a combination of knowledge, preparation, and vigilance. By following these safety guidelines, operators can minimize the risk of accidents and ensure a productive and secure work environment. Remember, safety should always be the top priority when working with powerful tools like the portable horizontal band saw.

English

English русский

русский عربى

عربى