Email: hujin@chinahujin.cn

Practices Examples for Using Steel Band Tools in Industrial Settings

Steel band tools, particularly precision band saws and horizontal band saws for metal, have become indispensable in various industrial settings. These tools are vital for achieving accurate cuts, enhancing efficiency, and ensuring the quality of metal components across different applications.

In the aerospace industry, precision is paramount. Steel band tools, such as precision band saws, play a crucial role in ensuring that components meet the exacting standards required for aerospace applications. These band saws are designed to deliver highly accurate cuts, which is essential for manufacturing parts that must adhere to tight tolerances and complex geometries. For example, components such as turbine blades and structural supports are often made from high-strength alloys that require precise cutting to achieve the necessary dimensions and surface finish. Precision band saws are equipped with advanced features, including programmable controls and adjustable speeds, to handle these demanding requirements effectively.

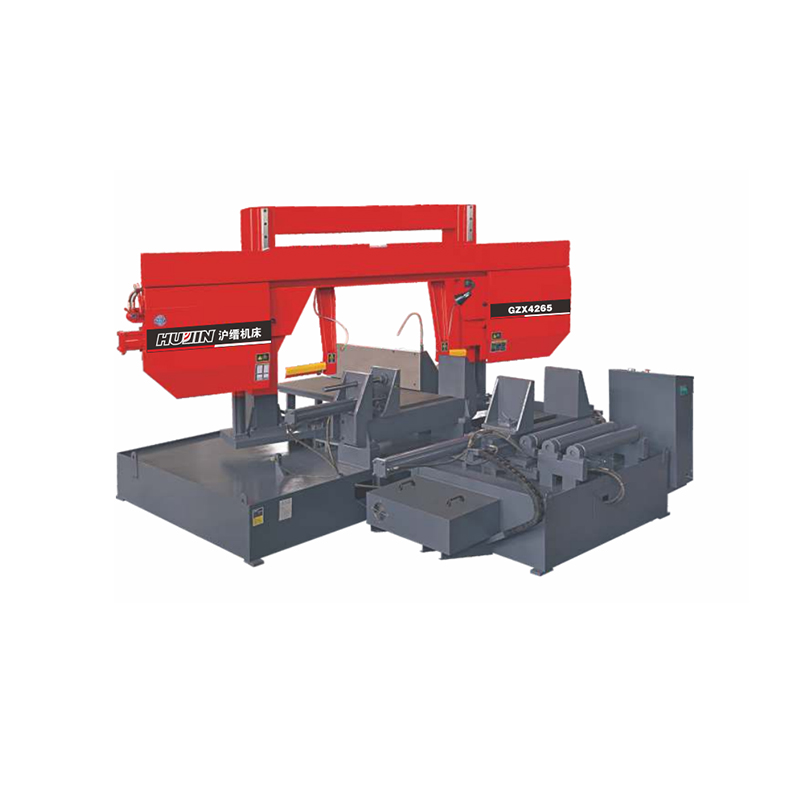

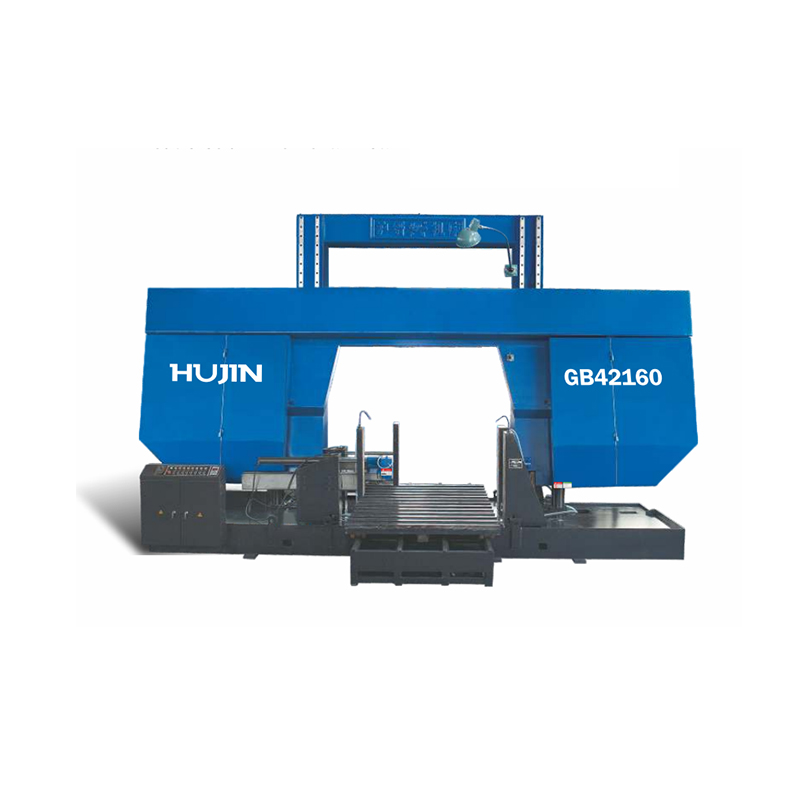

The automotive industry relies heavily on horizontal band saws for metal to handle high-volume production with efficiency and consistency. Horizontal band saws are particularly suited for cutting large sections of metal, such as engine blocks, chassis components, and structural beams. These machines offer robust performance and can cut through thick materials with precision, which is crucial for meeting production targets and maintaining quality standards. In a typical automotive production facility, horizontal band saws are used to prepare raw materials for further processing, ensuring that each component is cut to the correct size and shape before being subjected to additional manufacturing steps.

Structural steel fabrication is another field where steel band tools, especially horizontal band saws, are essential. In this industry, steel is cut into various shapes and sizes to create beams, columns, and other structural elements used in construction projects. Horizontal band saws for metal are employed to make straight cuts with high accuracy, which is vital for ensuring that steel components fit together correctly during assembly. The efficiency of horizontal band saws allows fabricators to process large quantities of steel quickly, which is important for meeting project deadlines and managing material costs.

Tool and die making requires a high level of precision and customization, and steel band tools are integral to this process. Precision band saws are often used to cut complex shapes and profiles required for manufacturing molds, dies, and specialized tools. These band saws offer the versatility needed to handle various materials and cutting requirements, making them ideal for custom metalwork. For instance, precision band saws can be used to cut intricate patterns into tool steel or hardened alloys, ensuring that the final products meet the specific design and performance criteria set by clients.

Architectural design often involves working with metal components that require precise cutting and shaping. Steel band tools, particularly precision band saws, are used to create intricate metal elements for architectural features such as facades, railings, and decorative structures. These saws provide the accuracy needed to achieve detailed designs and maintain high aesthetic standards. The ability to handle various metals and produce clean, precise cuts makes precision band saws an essential tool in the architectural metalworking industry.

In maintenance and repair operations, steel band tools are utilized to cut and reshape metal components that are worn or damaged. For example, precision band saws can be used to cut replacement parts for machinery, equipment, or infrastructure. The ability to quickly and accurately cut metal components is crucial for minimizing downtime and ensuring that repairs are completed efficiently. By using steel band tools, maintenance teams can produce high-quality replacement parts that restore equipment to its good condition.

English

English русский

русский عربى

عربى