Email: hujin@chinahujin.cn

- Home

- About

- Product

- NC Double-Column Horizontal Band Sawing Machine

- Horizontal Band Sawing Machine

- Rotary Horizontal Band Sawing Machine

- Double-Column Horizontal Metal Band Sawing Machine

- Vertical Band Sawing Machine

- NC Intelligent And Efficient Horizontal Band Sawing Machine

- Profile Cutting

- CNC High Speed Metal Circular Sawing Machine

- Service

- News

- Contact

INQUIRY NOW

Web Menu

- Home

- About

- Product

- NC Double-Column Horizontal Band Sawing Machine

- Horizontal Band Sawing Machine

- Rotary Horizontal Band Sawing Machine

- Double-Column Horizontal Metal Band Sawing Machine

- Vertical Band Sawing Machine

- NC Intelligent And Efficient Horizontal Band Sawing Machine

- Profile Cutting

- CNC High Speed Metal Circular Sawing Machine

- Service

- News

- Contact

Product Search

Exit Menu

Optimizing Double Column Band Saw Parameters for Diverse Material Cutting

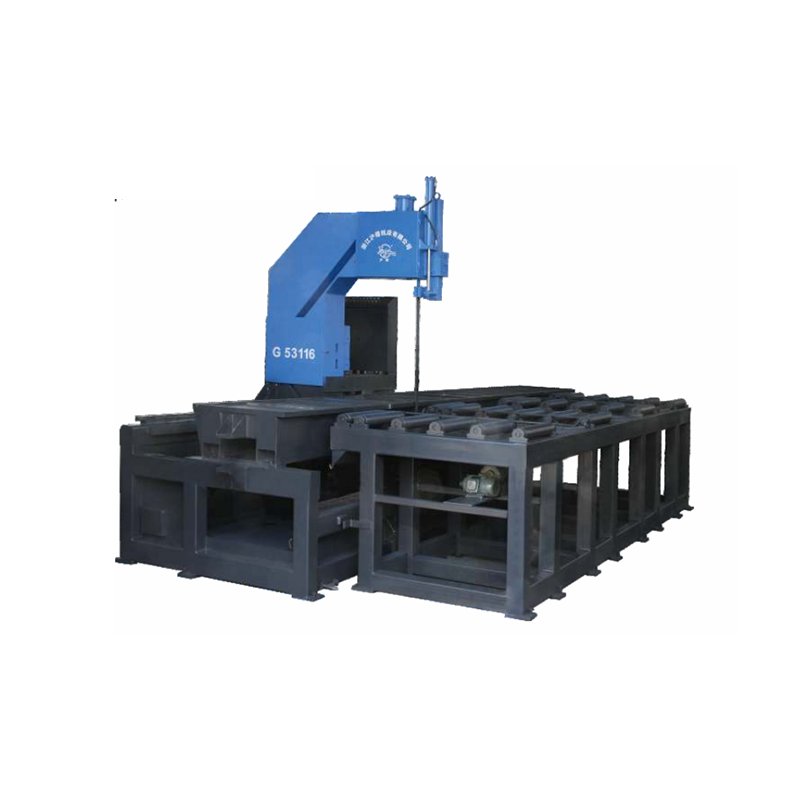

Wholesale OEM Automatic Double Column Band Saw Producer

The versatility of the Double Column Band Saw is a testament to its adaptability in various industrial applications. This robust sawing machine is capable of cutting through a multitude of materials, each with its unique properties that require specific adjustments to achieve suitable cutting performance. Understanding how to fine-tune the Double Column Band Saw for different materials is crucial for maintaining the precision, efficiency, and longevity of the saw. This article delves into the intricacies of parameter adjustments for the Double Column Band Saw when cutting different materials.

The Double Column Band Saw's ability to handle a variety of materials, from aluminum to steel, is a result of its design and the flexibility of its cutting parameters. The saw's performance is heavily influenced by the feed rate, blade tension, blade speed, and the choice of the blade itself. Each of these parameters must be carefully considered and adjusted to suit the material being cut.

When cutting softer materials like aluminum or copper, the Double Column Band Saw requires a slower feed rate to prevent the blade from binding or breaking. The blade tension should also be set to a lower level to accommodate the softer material, which is less likely to cause the blade to deflect. Conversely, when cutting harder materials such as steel, a higher feed rate can be used, and the blade tension should be increased to maintain blade stability and reduce the risk of blade breakage.

The blade speed of the Double Column Band Saw is another critical parameter that needs to be adjusted based on the material. For softer materials, a higher blade speed can be used to achieve a cleaner cut, while for harder materials, a lower speed is necessary to prevent excessive heat build-up, which can cause material warping or blade damage.

The choice of the blade for the Double Column Band Saw is also material-dependent. For example, when cutting aluminum, a bimetal blade with a fine tooth pitch is often used to achieve a smooth finish. In contrast, for steel, a blade with a coarser tooth pitch is more suitable to handle the increased resistance. The blade's tooth pitch and tooth shape also play a significant role in determining the cut quality and the saw's performance.

In addition to these adjustments, the Double Column Band Saw's cutting angle and the use of cutting fluids can also impact the cutting process. For materials prone to heat distortion, such as stainless steel, a cutting fluid can help to dissipate heat and reduce friction, causing a cleaner and more accurate cut. The cutting angle should be adjusted to ensure that the blade makes contact with the material at a suitable point, reducing the risk of blade wear and improving cut quality.

Regular maintenance of the Double Column Band Saw is also essential for maintaining its performance when cutting different materials. This includes checking and adjusting the blade tension, ensuring the saw's guide system is aligned, and replacing worn or damaged parts. Proper maintenance not only prolongs the life of the saw but also ensures that it can adapt to the varying demands of different materials.

In conclusion, the Double Column Band Saw's adaptability in cutting different materials is a result of its ability to adjust various parameters. By understanding the material properties and making the necessary adjustments to the feed rate, blade tension, blade speed, blade choice, cutting angle, and maintenance practices, users can optimize the performance of the Double Column Band Saw. This ensures not only efficient cutting but also the preservation of the saw's integrity and longevity, making it an invaluable asset in any metalworking operation.

Get in touch

Related Products

Zhejiang Hujin Machine Tool Co., Ltd. is a professional manufacturer specializing in the production of "Hurein" series hydraulic presses, band saws and milling machines.

Contact Information

phone: +86-18805885558

+86-13395785558

Email: hujin@chinahujin.cn

Add: No. 300, Xingda Road, Jinxiu Industrial Park, Huzhen Town, Jinyun County, Zhejiang Province, China 321404

Mobile Site

English

English русский

русский عربى

عربى