Email: hujin@chinahujin.cn

Key Features of a Profile Milling Tool for Precision Metalworking

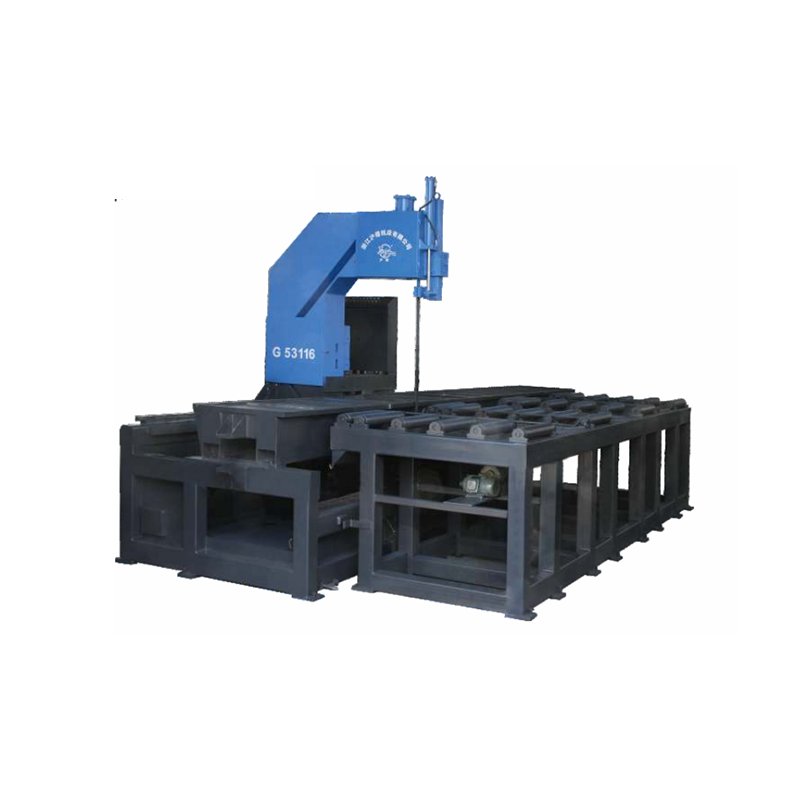

Among the various tools available, the profile milling tool stands out for its ability to achieve intricate and precise cuts in metal profiles. When integrated with advanced machinery like the CNC steel profile cutting machine and the profile light cutting machine, the profile milling tool becomes even more effective.

One of the defining features of a profile milling tool is its precision and accuracy. For metalworking applications, achieving exact dimensions and intricate details is crucial. The profile milling tool is engineered to handle complex geometric shapes with high precision, making it ideal for applications that require tight tolerances. When used in conjunction with a CNC steel profile cutting machine, which provides computer-controlled accuracy, the profile milling tool can deliver even greater precision. The CNC machine's ability to follow programmed specifications ensures that the profile milling tool cuts metal profiles with exacting detail, reducing the likelihood of errors and rework.

The versatility of the profile milling tool is another important feature. It is designed to handle various profile shapes, including angles, channels, and T-sections, allowing it to cater to a wide range of metalworking needs. This versatility is particularly useful when working with different types of metal profiles that require specific cutting techniques. The profile light cutting machine complements this versatility by providing a lighter, more agile cutting solution for thinner or more delicate profiles. Together, these tools enable metalworkers to tackle a diverse array of projects with ease and precision.

Efficiency is a critical factor in metalworking, and the profile milling tool contributes significantly to faster production times. The tool's design allows for rapid material removal and efficient processing of metal profiles. When paired with a CNC steel profile cutting machine, which automates and speeds up the cutting process, the overall efficiency of the metalworking operation is greatly enhanced. The combination of the profile milling tool and the CNC machine enables high-speed processing without sacrificing accuracy, cause increased productivity and reduced guide times.

Achieving a high-quality surface finish is essential in precision metalworking. The profile milling tool is specifically designed to produce smooth and clean cuts, which is critical for applications where surface quality is paramount. The tool's cutting edges are engineered to minimize chatter and vibration, resulting in a finer surface finish. Additionally, when used with a profile light cutting machine, which offers fine-tuning capabilities for delicate profiles, the profile milling tool can further enhance the overall surface quality. This combination ensures that the final product meets stringent aesthetic and functional requirements.

The profile milling tool offers a high degree of customization and adaptability, making it suitable for a range of metalworking tasks. The tool can be equipped with different inserts and cutters to accommodate various profile shapes and material types. This adaptability is particularly beneficial when working with specialized or custom metal profiles. The CNC steel profile cutting machine enhances this customization by allowing for programmable adjustments and precise control over cutting parameters. Together, these features provide metalworkers with the flexibility to tackle complex projects and meet specific client requirements.

Durability is a key consideration when selecting metalworking tools, and the profile milling tool is built to withstand the demands of high-precision cutting. Constructed from high-quality materials, the tool is designed for extended use and resistance to wear and tear. The profile milling tool's robustness ensures consistent performance over time, which is essential for maintaining precision in high-volume production. When paired with a profile light cutting machine, which is designed for both durability and precision, the overall longevity and reliability of the metalworking setup are enhanced.

Cost-effectiveness is a critical consideration in any metalworking operation. While high-quality profile milling tools may represent a significant initial investment, their efficiency and durability contribute to long-term cost savings. The combination of the profile milling tool with a CNC steel profile cutting machine and a profile light cutting machine offers a cost-effective solution by enhancing productivity and reducing material waste. The precision and efficiency of these tools cause better resource utilization and lower operational costs, making them a worthwhile investment for precision metalworking.

English

English русский

русский عربى

عربى