Email: hujin@chinahujin.cn

Innovations in CNC Band Saws: What's Changing in Metal Cutting Technology

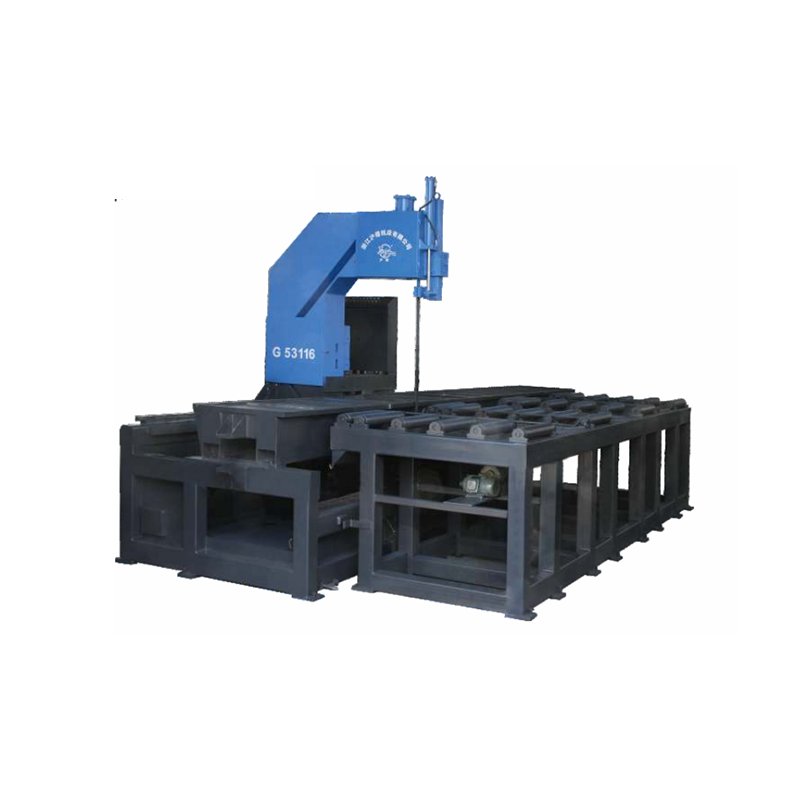

CNC band saws have revolutionized metal cutting by offering enhanced precision and automation. Unlike traditional band saws, CNC band saws integrate computer numerical control (CNC) technology to automate the cutting process, resulting in outstanding accuracy and efficiency.

1. Enhanced Automation and Control

Modern CNC band saws are equipped with advanced automation features that streamline the cutting process. These innovations include sophisticated CNC controls that allow operators to program complex cutting patterns and adjust parameters with precision. The integration of automated feed systems, automatic blade tension adjustments, and real-time monitoring enhances the efficiency and accuracy of industrial steel band saws. Operators can now execute intricate cuts with minimal manual intervention, significantly reducing production time and improving overall workflow.

2. Improved Cutting Speed and Efficiency

One of the notable advancements in CNC band saw technology is the improvement in cutting speed and efficiency. Newer models of CNC band saws, including industrial steel band saws, feature high-speed cutting capabilities that increase productivity. The incorporation of advanced materials and blade technologies has enabled these machines to cut through metal more quickly and with greater precision. This enhancement is particularly beneficial in high-volume production settings where speed and accuracy are critical.

3. Precision and Accuracy

The precision offered by CNC band saws has reached new heights with recent innovations. CNC band saws now include advanced blade guide systems and feedback mechanisms that ensure consistent cutting quality. Vertical band saw machines, known for their ability to handle complex cuts, have also benefited from these advancements. The precision of CNC technology allows for tight tolerances and complex geometries, making it ideal for applications that require exacting standards, such as aerospace and automotive components.

4. Versatility and Adaptability

Modern CNC band saws have become more versatile and adaptable to various cutting tasks. The ability to switch between different cutting modes and handle a wide range of metal types and sizes is a significant advancement. For example, industrial steel band saws are now capable of cutting through diverse materials, from mild steel to high-strength alloys, with ease. This versatility enables manufacturers to tackle a broader spectrum of projects without needing multiple specialized machines.

Vertical band saw machines have seen notable innovations that enhance their performance and functionality. These machines are particularly valued for their ability to handle intricate and irregular cuts, and recent advancements have further expanded their capabilities.

1. Advanced Blade Technology

One of the key innovations in vertical band saw machines is the development of advanced blade technology. Newer blades are designed to provide longer life, improved cutting performance, and reduced maintenance requirements. High-speed steel and carbide-tipped blades are now more commonly used, offering enhanced durability and precision for challenging cutting tasks. These advancements ensure that vertical band saw machines maintain their performance over extended periods, even with rigorous use.

2. Enhanced Cutting Precision

The integration of CNC technology in vertical band saw machines has significantly improved cutting precision. Advanced CNC controls enable operators to program complex cutting patterns and achieve highly accurate results. The incorporation of digital readouts and laser guides further enhances the precision of vertical band saw machines, allowing for intricate cuts and precise measurements.

3. Improved Safety Features

Safety remains a top priority in industrial settings, and vertical band saw machines have seen advancements in safety features. Modern machines are equipped with enhanced guarding systems, emergency stop functions, and automatic blade tensioning to ensure safe operation. These features help minimize the risk of accidents and improve overall safety in the workplace.

Innovations in CNC band saw technology are transforming the metal cutting industry, offering enhanced precision, efficiency, and versatility. The advancements in industrial steel band saws, vertical band saw machines, and CNC band saws reflect the ongoing progress in metal cutting technology. With improvements in automation, cutting speed, blade technology, and safety features, CNC band saws are setting new standards for high-quality metalwork. As technology continues to evolve, the future of CNC band saws promises even greater advancements, driving the industry towards more efficient and sustainable manufacturing practices.

English

English русский

русский عربى

عربى