Email: hujin@chinahujin.cn

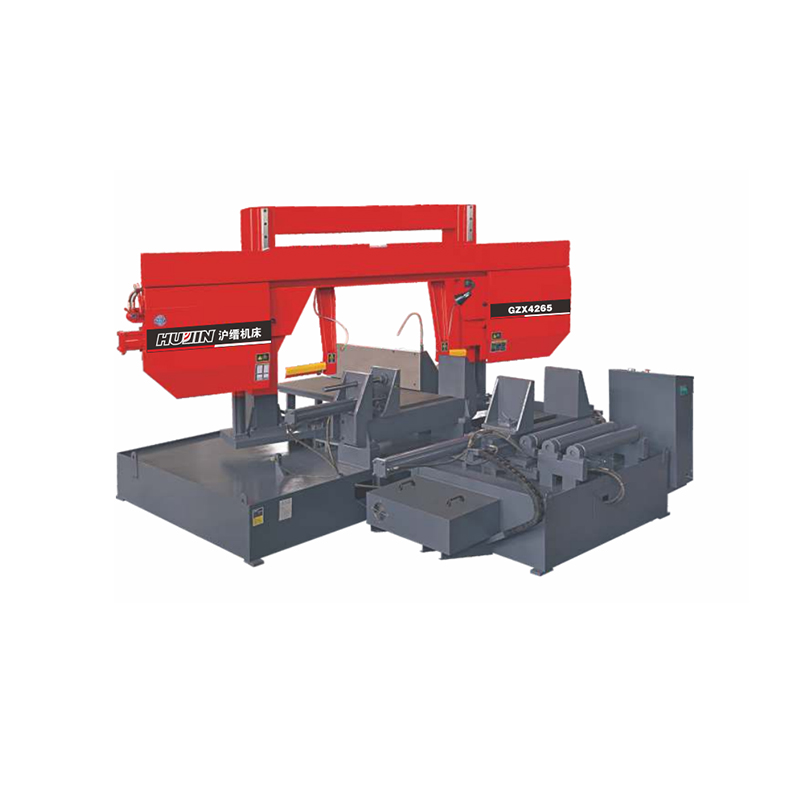

Evaluating the Performance of Double Column Band Saws in Cutting Various Metal Materials

Custom Automatic Double Column Band Saw Exporter in China

The versatility of the Double Column Band Saw in the metalworking industry is a testament to its robust design and engineering. This article will assess the performance of the Double Column Band Saw when cutting through different metal materials, examining how its capabilities adapt to the challenges posed by various material properties.

The Double Column Band Saw, with its dual-column structure, is designed to provide stability and precision during the cutting process. This stability is crucial when dealing with a range of metal materials, from soft metals like aluminum to hard metals such as steel. The saw's performance is not only a reflection of its mechanical design but also of the operator's ability to adjust settings to suit the specific material being cut.

When cutting softer metals like aluminum with a Double Column Band Saw, the saw can achieve high cutting speeds without compromising the quality of the cut. The softness of the material allows for faster feed rates, which can increase productivity. However, it is essential to maintain a balance between speed and the blade's tension to prevent blade damage or inaccurate cuts. The Double Column Band Saw's robust frame and precise control systems allow operators to make these adjustments with ease, ensuring that the saw remains efficient even when cutting softer materials.

In contrast, when the Double Column Band Saw is tasked with cutting harder metals such as steel, the saw's performance is put to a different test. Harder metals require slower cutting speeds to prevent excessive heat generation, which can cause material warping or blade wear. The Double Column Band Saw's sturdy construction and powerful motor are well-suited to these tasks, as they can maintain consistent cutting pressure even under the strain of cutting hard materials. Additionally, the saw's ability to adjust blade speed and feed rate allows operators to fine-tune the cutting process to achieve possible results.

Stainless steel presents a unique challenge for the Double Column Band Saw due to its high resistance to corrosion and its hardness. When cutting stainless steel, the saw must maintain a high level of precision to avoid deforming the material. The Double Column Band Saw's precision control systems and high-quality blades are up to this task, providing clean, accurate cuts even in the face of such challenging materials.

The Double Column Band Saw's performance with cast iron, a material known for its brittleness, is also noteworthy. The saw's ability to control cutting speed and feed rate is crucial in preventing the material from cracking or chipping. The saw's robust design and adjustable settings allow it to handle the unique demands of cutting cast iron, ensuring that the end product is free from defects.

In the case of titanium and other exotic metals, the double-column band Saw's performance is a testament to its adaptability. These materials often require specialized cutting tools and techniques due to their strength and resistance to heat. The Double Column Band Saw's advanced features, such as variable speed control and precision blade guidance, make it well-equipped to handle the complexities of cutting these advanced materials.

In conclusion, the Double Column Band Saw's performance in cutting various metal materials is a result of its design, engineering, and the operator's ability to adjust its settings to suit the specific material. Whether cutting soft metals like aluminum or hard materials such as steel, the Double Column Band Saw's adaptability and precision control systems ensure that it remains a reliable and efficient tool in the metalworking industry. Its performance is a clear indication of its over other types of saws, making it the preferred choice for professionals who demand high standards in their cutting operations.

English

English русский

русский عربى

عربى