Email: hujin@chinahujin.cn

Essential Maintenance Tips for Horizontal Metal Cutting Bandsaw Machines

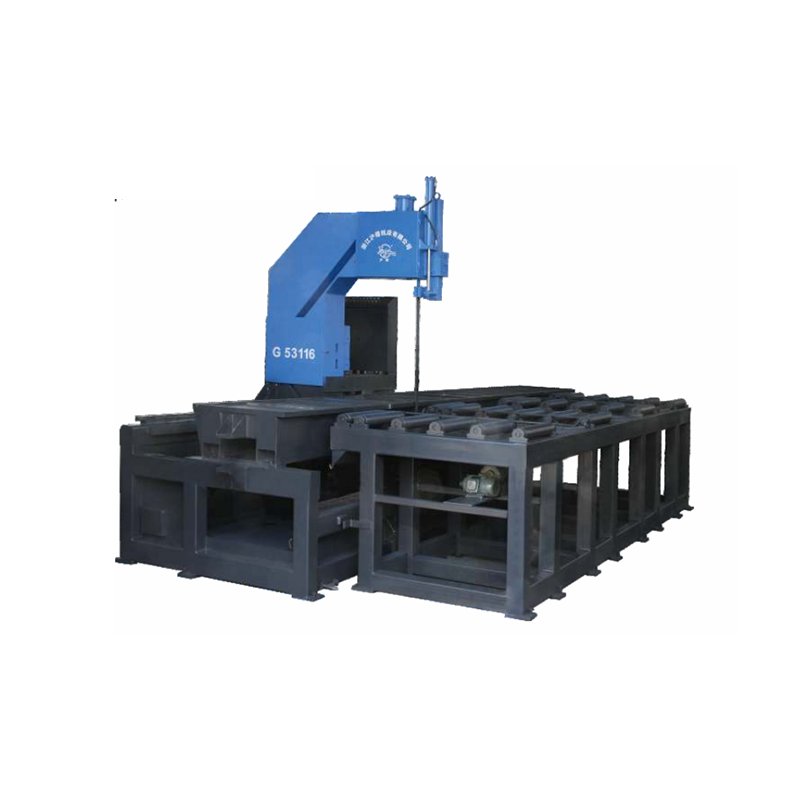

The horizontal metal cutting bandsaw machine is a staple for its versatility and efficiency in cutting various materials. However, to ensure good performance and longevity, regular maintenance is crucial.

The step in maintaining any machinery is recognizing its importance. Regular maintenance not only prevents costly repairs but also enhances the performance and lifespan of your horizontal metal cutting bandsaw machine. It is an investment that pays off by reducing downtime and ensuring that your saw remains reliable and precise.

Begin with a routine inspection of your automatic metal band saw. Check for any signs of wear and tear, such as frayed or damaged bands, loose bolts, or misaligned components. Early detection of these issues can prevent more significant problems down the line.

The band is the heart of your hydraulic metal band saw. Inspect it for any signs of wear, such as notches or uneven edges. Replace the band if it's no longer cutting cleanly or if it's showing signs of fatigue. Remember, a well-maintained band will ensure cleaner cuts and less strain on the machine.

Lubrication is key to reducing friction and heat buildup in your horizontal metal cutting bandsaw machine. Regularly lubricate the guide bearings and the band itself to ensure smooth operation. The right lubricant can extend the life of your band and reduce the risk of jams.

Correct tension is vital for the performance of your automatic metal band saw. Too loose, and the band may wander or break; too tight, and it can cause excessive wear. Regularly check and adjust the tension according to the manufacturer's recommendations and the type of material you're cutting.

Misaligned guides or wheels can cause uneven band wear and poor cutting quality. Ensure that the guides are clean, free of debris, and properly aligned with the wheels. This will help maintain the straightness of the cut and prolong the life of your band.

A clean hydraulic metal band saw is a happy one. Regularly clean your machine to remove metal shavings, dust, and other debris that can cause damage or affect performance. Pay special attention to the areas around the band and the guide system.

For horizontal metal cutting bandsaw machines with electrical or hydraulic components, regular checks of these systems are essential. Inspect for any leaks, corrosion, or signs of electrical issues. Addressing these problems early can prevent more extensive damage.

Ensure that all operators are properly trained on the safe use and maintenance of your horizontal metal cutting bandsaw machine. Understanding the machine's functions and maintenance requirements can prevent accidents and improve overall performance.

Implement a scheduled maintenance program for your automatic metal band saw and hydraulic metal band saw. Regular servicing by a professional or a knowledgeable in-house team can identify and address issues before they become critical.

Maintain a log of all maintenance activities, including inspections, replacements, and repairs. This record can help you identify patterns or recurring issues and can be invaluable for planning future maintenance.

By following these essential maintenance tips, you can keep your horizontal metal cutting bandsaw machine running smoothly and efficiently. Remember, a well-maintained saw is not only safer but also more productive, helping you to meet your metalworking needs with confidence.

English

English русский

русский عربى

عربى