Email: hujin@chinahujin.cn

Durability of Blade Bands in Small Bandsaw Machines

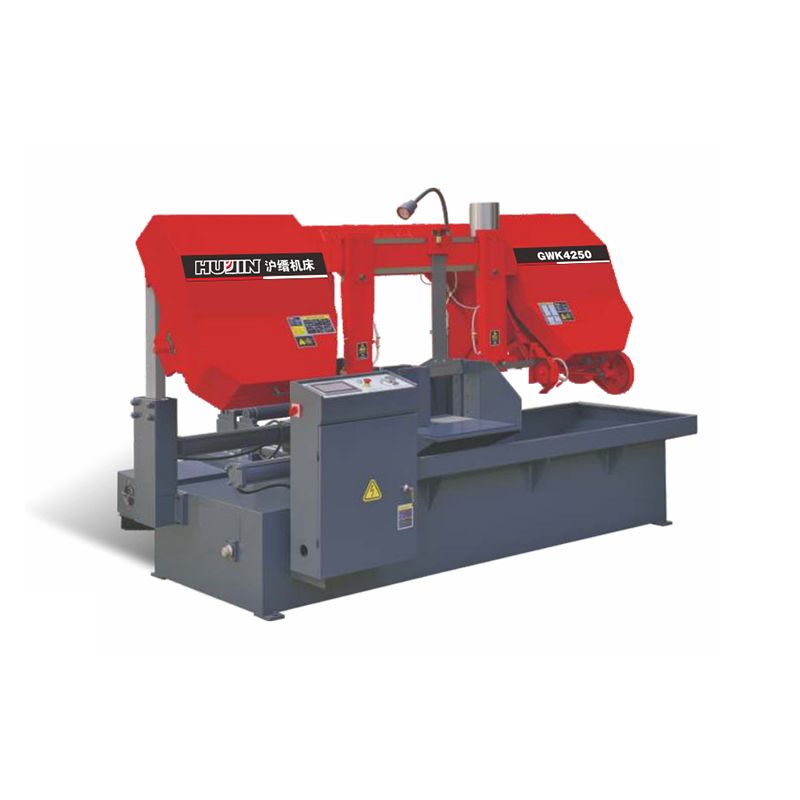

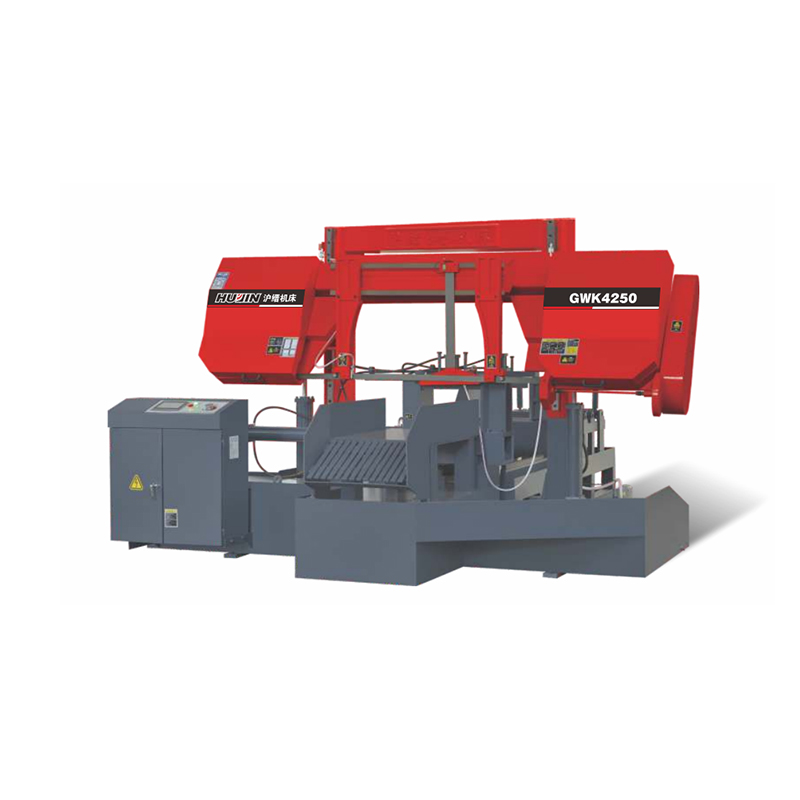

Custom Design Small Bandsaw Machine Manufacturing Maker

The small bandsaw machine, a staple in many workshops and garages, is renowned for its versatility and precision in cutting a variety of materials. However, the durability of the blade bands used in these machines is a critical factor that directly impacts the overall performance and longevity of the tool. This article aims to explore the various aspects that contribute to the durability of blade bands in small bandsaw machines, examining the materials, manufacturing processes, and usage patterns that can influence their lifespan.

The blade bands of a small bandsaw machine are typically made from high-quality steel, which is chosen for its strength and resistance to wear. The manufacturing process involves a series of heat treatments and tempering stages that enhance the steel's hardness and flexibility. This ensures that the blade bands can withstand the stress of repeated cutting without losing their sharpness or structural integrity.

One of the primary factors affecting the durability of blade bands in small bandsaw machines is the quality of the steel used. High-carbon steel is often preferred due to its good edge retention and resistance to chipping. However, the addition of other elements such as chromium, vanadium, or molybdenum can further improve the blade's resistance to wear and corrosion, thus extending its service life.

The manufacturing process also plays a significant role in determining the durability of blade bands. Precision grinding and sharpening are essential to ensure that the blade has a consistent and sharp edge. This not only improves the cutting performance but also reduces the risk of the blade band breaking or deforming under stress. Additionally, the process of heat treatment must be carefully controlled to achieve the right balance between hardness and toughness, as an overly hard blade may be brittle and prone to breakage.

The design of the small bandsaw machine itself can also impact the durability of the blade bands. Machines that feature adjustable tension systems allow users to maintain the correct tension on the blade, which is crucial for preventing premature wear and tear. Furthermore, the guide system, which includes the upper and lower guide blocks, must be aligned and maintained to ensure that the blade runs straight and true. Misalignment can cause the blade to vibrate excessively, causing accelerated wear and potential breakage.

Usage patterns are another critical factor to consider when assessing the durability of blade bands in small bandsaw machines. Overloading the blade by cutting materials that are too hard or too thick for the blade's capacity can cause rapid wear and even breakage. Similarly, cutting at high speeds can generate excessive heat, which can weaken the steel and reduce the blade's lifespan. Users need to follow the manufacturer's recommendations for the appropriate cutting speeds and feed rates for their specific small bandsaw machine and blade band combination.

Regular maintenance is also crucial for prolonging the life of blade bands in small bandsaw machines. This includes cleaning the blade after each use to remove any debris or coolant that may have accumulated, as well as periodically inspecting the blade for signs of wear or damage. Sharpening the blade when necessary can help maintain its cutting performance and prevent excessive wear. Additionally, ensuring that the tension and guide systems are properly adjusted and aligned can help reduce the stress on the blade and prolong its life.

In conclusion, the durability of blade bands in small bandsaw machines is a complex interplay of material quality, manufacturing processes, machine design, and user practices. By selecting high-quality blade bands made from the appropriate materials, ensuring that the small bandsaw machine is properly designed and maintained, and following the recommended usage guidelines, users can improve the lifespan of their blade bands and enjoy suitable performance from their small bandsaw machines. Regular maintenance and attention to detail are key to ensuring that these essential tools remain reliable and efficient for years to come.

English

English русский

русский عربى

عربى