Email: hujin@chinahujin.cn

Cutting Precision of Automatic Band Saw Machine Comprehensive Analysis

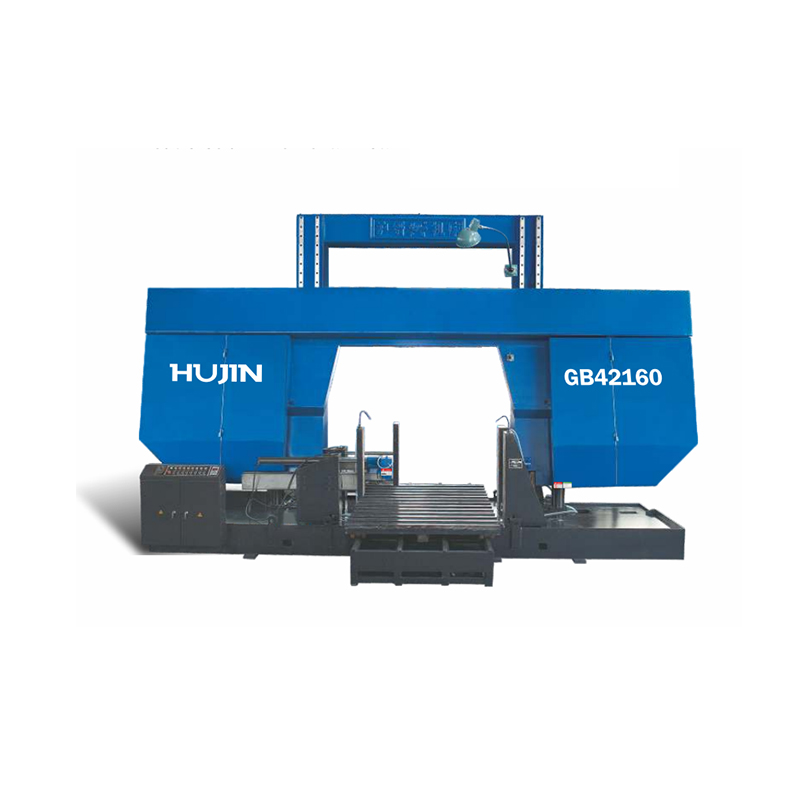

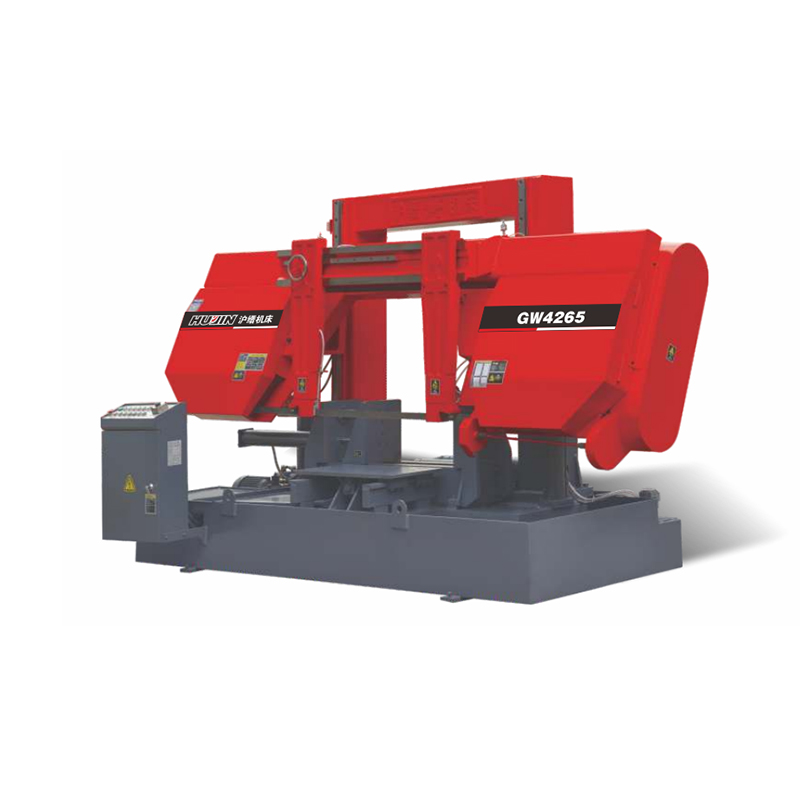

High Quality Automatic Band Saw Machine Manufacturing Maker

In the realm of metalworking and woodworking, precision is paramount. The Automatic Band Saw Machine has carved a niche for itself as a tool of choice for its good cutting precision. This article aims to explore the intricacies of the Automatic Band Saw Machine's cutting precision, examining the factors that contribute to its accuracy and the technological advancements that have made it a reliable choice for various industries.

The Automatic Band Saw Machine's precision is a result of a combination of its mechanical design, the quality of its components, and the sophistication of its control systems. The machine's cutting precision is influenced by several factors, including the tension of the band saw blade, the alignment of the blade, the feed rate, and the material being cut.

The blade tension is a critical aspect of the Automatic Band Saw Machine's operation. A properly tensioned blade ensures that the blade remains straight and true during the cutting process, which is essential for achieving precise cuts. The tension is typically adjusted using a mechanical or hydraulic system, which allows for fine-tuning to suit the specific requirements of the material being cut.

The alignment of the blade is another crucial factor that affects the cutting precision of the Automatic Band Saw Machine. Misaligned blades can cause uneven cuts and potential damage to the blade or the workpiece. The machine's design typically includes a system for ensuring that the blade is correctly aligned with the cutting guide and the workpiece. This alignment is maintained through the use of precision bearings and guides that keep the blade on a true path.

The feed rate of the Automatic Band Saw Machine is a variable that can be adjusted to achieve the desired level of precision. A slower feed rate allows for more control over the cutting process, which can result in more precise cuts. However, this comes at the cost of reduced productivity. On the other hand, a faster feed rate can increase productivity but may sacrifice some precision. The balance between precision and productivity is a key consideration when operating an Automatic Band Saw Machine.

The material being cut also plays a significant role in the cutting precision of the Automatic Band Saw Machine. Different materials have different hardness levels, grain patterns, and other characteristics that can affect how the blade cuts through them. For instance, cutting through a dense hardwood may require a different approach than cutting through a softwood. The machine's operator must be aware of these differences and adjust the machine's settings accordingly to achieve the possible precision.

Technological advancements have also played a significant role in improving the cutting precision of the Automatic Band Saw Machine. Modern machines often feature computer numerical control (CNC) systems that allow for precise control over the cutting process. These systems can be programmed to make complex cuts with a high degree of accuracy, making them ideal for industries that require precision manufacturing.

In addition to CNC systems, other technological innovations such as laser guidance and digital readouts have further enhanced the precision of the Automatic Band Saw Machine. These tools provide real-time feedback on the cutting process, allowing operators to make adjustments on the fly to ensure a high level of precision.

Maintenance and proper operation of the Automatic Band Saw Machine are also essential for maintaining cutting precision. Regular maintenance, including blade sharpening and alignment checks, ensures that the machine remains in suitable condition. Proper operation, including following safety guidelines and adhering to the manufacturer's recommendations, also plays a crucial role in achieving precision cuts.

In conclusion, the cutting precision of the Automatic Band Saw Machine is a result of a complex interplay of factors, including blade tension, alignment, feed rate, material characteristics, and technological advancements. By understanding and controlling these factors, operators can achieve the high level of precision that the Automatic Band Saw Machine is known for. As technology continues to advance, likely, the precision capabilities of these machines will likely only improve, further solidifying their place as a critical tool in the world of metalworking and woodworking.

English

English русский

русский عربى

عربى