Email: hujin@chinahujin.cn

- Home

- About

- Product

- NC Double-Column Horizontal Band Sawing Machine

- Horizontal Band Sawing Machine

- Rotary Horizontal Band Sawing Machine

- Double-Column Horizontal Metal Band Sawing Machine

- Vertical Band Sawing Machine

- NC Intelligent And Efficient Horizontal Band Sawing Machine

- Profile Cutting

- CNC High Speed Metal Circular Sawing Machine

- Service

- News

- Contact

INQUIRY NOW

Web Menu

- Home

- About

- Product

- NC Double-Column Horizontal Band Sawing Machine

- Horizontal Band Sawing Machine

- Rotary Horizontal Band Sawing Machine

- Double-Column Horizontal Metal Band Sawing Machine

- Vertical Band Sawing Machine

- NC Intelligent And Efficient Horizontal Band Sawing Machine

- Profile Cutting

- CNC High Speed Metal Circular Sawing Machine

- Service

- News

- Contact

Product Search

Exit Menu

Benefits of Using a Steel Cutting Vertical Bandsaw for High-Precision Cuts

In the realm of metalworking, precision and efficiency are paramount. A key tool that exemplifies these qualities is the steel cutting vertical bandsaw. This equipment is essential for achieving high-precision cuts in steel and other metals, and it brings numerous benefits to workshops and industrial settings alike.

A steel cutting vertical bandsaw is specifically designed to deliver outstanding precision and accuracy. Its vertical orientation allows for better visibility and control during the cutting process, which is crucial for achieving exact measurements and clean edges. This precision is vital for applications that demand tight tolerances and intricate details, such as in the automotive, aerospace, and construction industries.

The steel cutting vertical bandsaw excels in producing smooth, precise cuts, reducing the need for secondary finishing processes. This advantage not only saves time but also ensures the integrity of the cut edges, which is critical for parts that will be assembled or welded.

One of the significant benefits of a steel cutting vertical bandsaw is its versatility. It can handle a wide range of materials, including various grades of steel, aluminum, and other metals. This flexibility makes it an invaluable tool in workshops that deal with multiple types of materials.

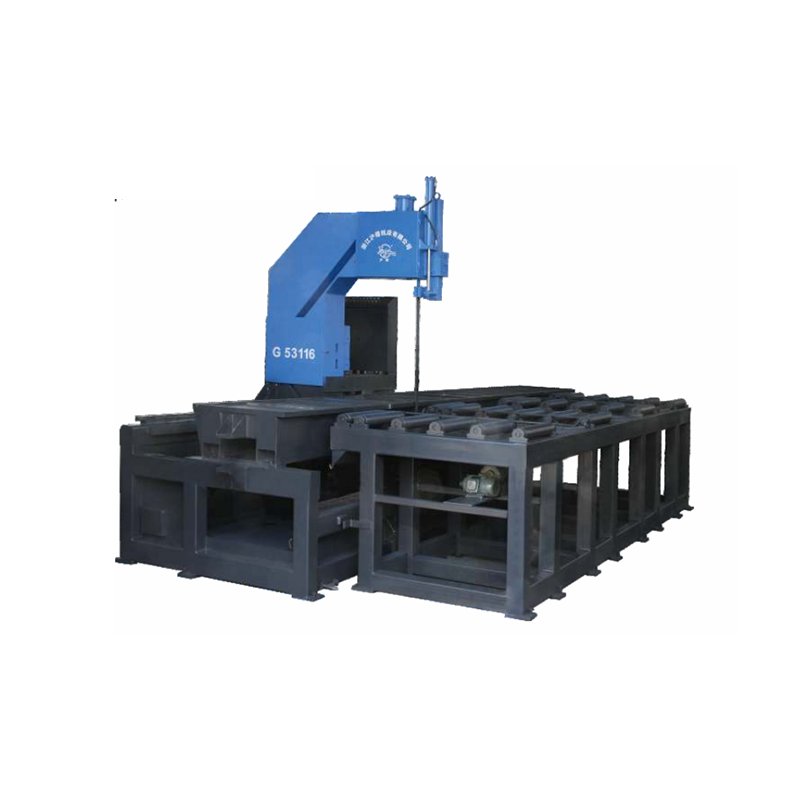

Compared to a benchtop vertical bandsaw, which is typically used for smaller, lighter tasks, the steel cutting vertical bandsaw is built to handle more demanding applications. Its robust construction and powerful motor allow it to cut through thicker and harder materials with ease, making it suitable for heavy-duty industrial use.

Efficiency is a key factor in any manufacturing or metalworking environment. The steel cutting vertical bandsaw is designed to enhance productivity by enabling faster and more accurate cuts. Its vertical design allows for easy handling of large and heavy workpieces, reducing the effort and time required to maneuver materials into position.

When comparing it to a horizontal metal cutting saw, the steel cutting vertical bandsaw offers distinct advantages. While horizontal metal cutting saws are outstanding for cutting long, straight pieces, they often require more space and setup time. The vertical bandsaw, on the other hand, can accommodate a variety of cutting tasks with minimal adjustment, making it more versatile and time-efficient.

Workshops often face space constraints, and the steel cutting vertical bandsaw's compact design helps improve available workspace. Unlike horizontal metal cutting saws, which can take up significant floor space, the vertical bandsaw's upright orientation allows it to fit comfortably in smaller areas. This space-saving design is particularly beneficial for smaller workshops or those looking to optimize their layout for increased efficiency.

Safety is a critical concern in any workshop, and the steel cutting vertical bandsaw is designed with operator safety in mind. Features such as blade guards, emergency stop buttons, and adjustable blade speeds help ensure safe operation. Additionally, the vertical design allows operators to maintain a comfortable and ergonomic working position, reducing the risk of fatigue and injury.

The steel cutting vertical bandsaw is also user-friendly, with intuitive controls and easy-to-adjust settings. This ease of use makes it accessible for operators of varying skill levels, from novices to experienced professionals.

While the initial investment in a steel cutting vertical bandsaw may be higher compared to a benchtop vertical bandsaw or a horizontal metal cutting saw, the long-term benefits often outweigh the costs. The precision and efficiency provided by the vertical bandsaw reduce material waste and the need for additional finishing processes, cause significant cost savings over time.

Moreover, the durability and reliability of a steel cutting vertical bandsaw mean less frequent maintenance and replacement, further enhancing its cost-effectiveness. For workshops looking to invest in a tool that offers high precision and longevity, the steel cutting vertical bandsaw is an outstanding choice.

While benchtop vertical bandsaws and horizontal metal cutting saws have their own advantages, the steel cutting vertical bandsaw stands out as the versatile and effective choice for high-precision metal cutting tasks. By investing in a steel cutting vertical bandsaw, workshops can enhance their productivity, ensure high-quality results, and optimize their operations for long-term success.

Get in touch

Related Products

Zhejiang Hujin Machine Tool Co., Ltd. is a professional manufacturer specializing in the production of "Hurein" series hydraulic presses, band saws and milling machines.

Contact Information

phone: +86-18805885558

+86-13395785558

Email: hujin@chinahujin.cn

Add: No. 300, Xingda Road, Jinxiu Industrial Park, Huzhen Town, Jinyun County, Zhejiang Province, China 321404

Mobile Site

English

English русский

русский عربى

عربى